Excavator buckets are attachments specially made for excavators. They are large construction equipment designed for trenching, digging and earthmoving and mining work. Buckets are the main tools used by excavators for scooping, lifting, and moving various materials like soil, rocks, dirt and other aggregates.

These are the Types of Excavator Buckets:

Mining Bucket

Mining buckets, sometimes referred to as mine Backhoe buckets or excavator mining bucket is, a specific excavator buckets made especially for use in mining. It is utilized in mining projects of a large scale to move bulk materials like coal overburden, ore, and various other materials or minerals used in mining.

Key characteristics:

- High Capacity: Carrying capacity that helps increase productivity in mining operations.

- Reinforced Structure: Resist the abrasion and impact that occurs in mining operations.

- Tooth System The teeth are specially designed or adapters that are designed specifically for use in mines.

Shovel Bucket

A Hydraulic or electric shovel bucket also referred to as a face shovel bucket or an attachment for shovels, is a special type of bucket made to be used with hydraulic or power shovels. Power shovels are massive excavating equipment that is commonly used for mining and other heavy-duty earthmoving tasks.

Key characteristics:

- Large Capacity such that maximum quantity of material that can be lifted and loaded on every cycle.

- Reinforced Structure: withstand the stress of excavations that are heavy-duty.

- Dumping Method: Allow controlled dumping of materials.

Excavator Bucket

ABackhoe excavator bucket is a Type of Excavator Buckets designed specifically for excavators. Excavators are large construction equipment that are used to dig trenches, digging and earthmoving jobs.

Important feature:

- Cutting Edges or Teeth Cutting Edges or Teeth on the front of the bucket.

- Bucket Capacity: refers to the quantity of material it can hold and designed as per the capacity of the excavator.

- Reinforced Structure: withstand the demands from excavation works.

Wheel Loader Buckets

The buckets of a wheel loader are specially designed attachments made specifically for wheel loaders. They are heavy equipment devices that are used to load and transport materials used in mining, construction and other fields.

Key characteristics:

- Bucket Capacity: Suitable for various needs and applications.

- Cutting Edges: The bucket is equipped with teeth or a bolt-on cutting edge along the front edge of the bucket.

- Bucket Shape: Many designs are based on the purpose of usage.

Hi Temperature Buckets

Hi-temperature buckets, also referred to as heat-resistant or high-temperature buckets, are specially-designed Types of Excavator Attachments made to work with materials in high temperatures. They are typically employed in industrial processes that require materials to be handled in high temperatures, such as hot metals and molten slag.

Most important features:

- Materials that resist heat: Special steel grades that can withstand the extreme temperatures experienced during use.

- Design: Design that protects the operator as well as the machine from heat transfer that is too high.

Side Dump Bucket

The side dump bucket, also referred to by the name of a side discharge bucket or side dump attachment, is a special kind of bucket that is designed for wheel loaders and Backhoe Loaders. It’s designed to facilitate an efficient and controlled lateral release of material during stockpiling or loading processes.

Key characteristics:

- Lateral Discharge: Allows controlled discharge of substances from the sides of the bucket.

- Hydraulically operated: Allowing the operator to manage how the bucket sides open and close. Sides of the bucket.

- High Capacity: Allowing you to manage large amounts of material in one dump operation.

Single Side Dump

A single-side dump bucket, also referred to by the name of a single-side discharge bucket, is a specific attachment that was designed for wheel loaders and Backhoe Loaders. It’s used to ensure efficient disposal of material during stockpiling or loading processes.

Key characteristics:

- Lateral Discharge: The ability to discharge material laterally from one side of the bucket to the other side.

- Hydraulically operated: Hydraulically controlled allows the operator to regulate that the speed of discharge and bucket opening and closing.

- Adjustable Discharge Angle: Discharge angle is adjustable, which allows the operator to change the direction and extent of the material to be dumped.

Dual Side Dump

A dual-side dump bucket, also referred to as a double-side discharge bucket, is a specific attachment that was designed for wheel loaders and Backhoe Loaders. It allows for an efficient and controlled lateral discharge of material on either side of the machine when loading or stockpiling.

The key features are:

- Lateral discharge from both sides: The discharge of materials is laterally on both sides of the bucket.

- Hydraulic Operated: Fitted hydraulic cylinders and valves, which allow for the closing and opening of each drain.

- High Capacity: havehigher capacity, allowing them to handle large amounts of material.

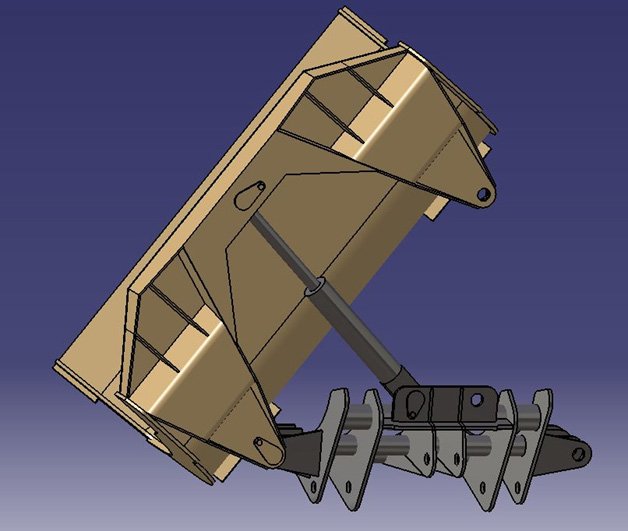

Coal Crushing Bucket

The coal crusher bucket also referred to as a coal crusher and screening bucket or coal pulverizing bucket, is a special attachment made for loaders or excavators. It is specially designed to crush and pulverize coal or coal-like substances into smaller pieces.

The key features are:

- Crushing Mechanism: Blades or teeth that are designed to break up and crush coal and coal-like materials.

- The High Crushing Performance: Effectively crush huge amounts of coal in one operation.

- Reinforced Structure: Strong and reinforced structure designed to resist the force created.

Scoop / Block Handling Bucket

A scoop bucket for handling is also referred to as a material-handling bucket or scoop bucket. It is an attachment for wheel loaders and Excavators. It is utilized for handling large blocks of rock such as Granite and Marble and concrete slabs.

The key features are:

- Scoop Design: Choose an open and shallow design with a rounded or curly bottom.

- The High-Volume Capacity: It is designed with a large capacity that allows for greater amounts of material.

- Reinforced Structure: Designed with a strong and sturdy structure that can withstand the load.

Trapezoidal Trench Bucket

A trapezoidal trench bucket, often referred to as a V-shaped trench bucket or trapezoidal ditching bucket, is a special attachment made for excavators. It is used to dig and shape ditches or trenches that have a trapezoidal cross-section.

Key characteristics:

- Trapezoidal Shape Trapezoidal Shape: Wider opening on the top and an opening that is narrower towards the bottom.

- Tapered sides: The sides of the trapezoidal trench bucket taper downwards from the top of the bucket towards the base.

- Wear protection and bolt-on teeth.

Perforated Bucket

The perforated bucket, also referred to as a screening bucket or sieve bucket, is an attachment that is designed for excavators as well as loaders. It is used to sort and separate material by size, allowing smaller particles to go through.

The key features are:

- Perforated Design: characterized by its construction using an array of evenly spaced holes.

- Customizable Pattern and Size of Hole The pattern and size of the slots or holes inside the bucket are adjusted to meet your particular requirements for sorting.

- Reinforced Structure: Designed with a sturdy and reinforced structure designed to stand up to the pressures experienced during sorting.

Micro Trenching Bucket

Micro trenching buckets are an attachment that is specifically designed for backhoes and excavators that are used in a technique of construction known as micro trenching. Micro trenching is the process of creating narrow and slender trenches to allow for the installation of utility lines.

The key features are:

- Narrow Width: Created using a narrow width, it can be used to make trenches with particular dimensions that are required in micro trenching.

- Shallow Depth involves excavating shallow trenches.

- Clean Cutting Edges Cut edges in micro trenching buckets are designed to give an accurate and clean cut.

V Bucket

An V bucket also referred to as a V-shaped bucket or V-ditching, is a specific attachment that is designed for backhoes or excavators. It is employed for digging and shaping channels or ditches that are V-shaped.

The most important features:

- V-shaped design: The bucket features a V-shaped design, which resembles the letters “V” when viewed from the front.

- Tapered Sides These sides taper downwards from the top of the bucket towards the base.

- This could include wear protection as well as bolt-on cutting edges and bolt-on teeth.

Digging Bucket

The digging bucket is, also referred to as an excavating bucket or general-purpose bucket, is a widely utilized attachment to excavators. It was specifically designed for general excavation and tasks like digging, loading and bulk material handling.

Most important characteristics:

- Buckets’ Shape and Capacity The buckets are available in a variety of sizes and shapes based on the requirements specific to the excavation job.

- Teeth System equipped with a toothed mechanism that includes replaceable teeth or worn parts located on the edge of the bucket’s leading edge.

- They could include wear protection as well as bolt-on cutting edges for better cutting performance and longer bucket life.

Rock Bucket

The rock bucket, sometimes referred to as an excavation bucket for rock or rock Grading buckets, is a specific attachment that is designed for excavators as well as loaders. It is designed specifically to handle and sort rocks.V Engineering Enterprise buckets are specially designed for digging and handling rocks.

The key features are:

- Heavy-Duty Construction: Designed with an extremely durable construction that can be able to withstand the harsh nature of excavation rock.

- Wide Openings: They have greater openings when compared with buckets for general use.

- Multi-purpose: Mostly employed for excavation of rock buckets for rock excavation, they can also be used to transport rocks.

Grading Bucket

A grading or land-leveling bucket also called a grading or land-leveling bucket, is a special attachment for loading machines or excavators. It is used to fine-grade and level surfaces in order to get an even and smooth appearance.

The most important features:

- Flat Bottom: Allows for uniform and consistent distribution of materials in grading operations.

- Wide Width Grading buckets are generally bigger than conventional digging buckets.

- Low profile: Aids ensure visibility to the operator when grading.

Excavator buckets are essential Types of Excavator Attachments that allow excavators to perform efficiently many different earth-moving, construction and digging tasks across a variety of sectors, such as construction, landscaping, mining, as well as road maintenance.